HOME > Functional Films > Nanoimprint

Functional Films

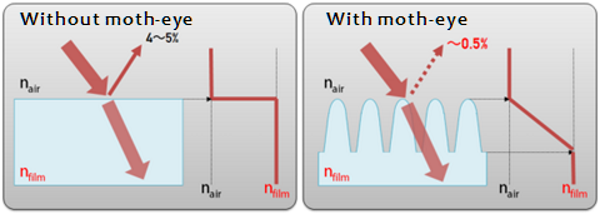

The moth-eye structure, created by biomimetic technology, has an uneven structure of several hundred nanometers and significantly reduces reflection in the visible light range. Due to its anti-reflection function, high contrast and transparency, it is attracting attention as a structure that suppresses surface reflection and glare for display and digital signage applications.

Nanoimprinting is a microfabrication technology in which a "mold" with microscopic irregularities like a moth-eye structure is heat-pressed or UV-irradiated onto resin to transfer the shape of the mold.

Biomimetic technology is a technology that mimics biological methods and systems found in the natural world to help design engineering systems and technologies.

Applications

Anti-reflection function

Moth-eye

Unlike conventional anti-reflection coatings, it does not require multi-layer

coating. The anti-reflective effect is achieved by nanoimprinting to create

a sub-wavelength scale surface profile. The INOX nanostructure uses a moth-eye

structure. The moth-eye shape creates a gradual refractive index distribution

that reduces the visible light reflectance from 4% to less than 0.5%.

R&D mold >HT-AR: Moth-eye

R&D mold >HT-AR: Moth-eye

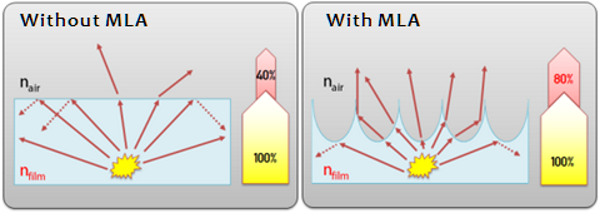

Light extraction enhancement function

MicroLens Array (MLA)

Compared to conventional microlenses of the same size, there is no dead space between the lenses, and the microstructure enables uniform control of the output light.

R&D Mold >HT-MLA: MLA

R&D Mold >HT-MLA: MLA

Optical Control

Engineered Diffuser

The special light distribution structure on the surface enables light to be diffused evenly while maintaining high transmittance. This structure can control the light emitted from general light sources, lasers, LEDs, lighting fixtures, and backlights used in LCDs, etc.

R&D Mold>HT-ED: Engineered Diffuser

R&D Mold>HT-ED: Engineered Diffuser

We provide molds of moth-eye, microlens, and light distribution diffusion structures fabricated by interference lithography method for nanoimprinting R&D.

We offer trial production of film samples for companies that do not have the initial study of nanoimprinting or imprinting equipment. We can process various plastic and glass substrates. Adhesive processing is also available.

We can handle large mold area by interferential lithography and special structure by special mask or maskless method. We also offer services related to molds, such as joining small molds together and special electroforming copying (which prevents the destruction of the master mold).

temicon

IMRE