HOME > Functional Films > Nanoimprint > R&D mold

Functional Films

We provide molds of moth-eye, microlens, and light distribution diffusion structures fabricated by interference lithography method for nanoimprinting R&D.

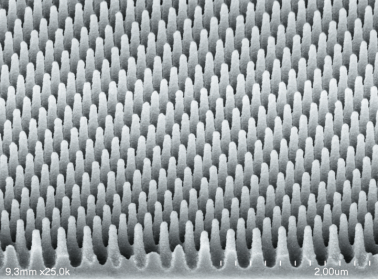

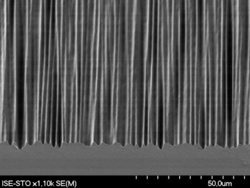

Interference between two laser beams forms micro- and nano-structures over a wide area. The laser beam is split by a splitter and magnified to form interference fringes for exposure, eliminating the need for a mask. The pattern is recorded on a photosensitive material. By rotating the substrate and adjusting the interference of the laser, the shape of the pattern to be formed can be changed, making it possible to create complex structures.

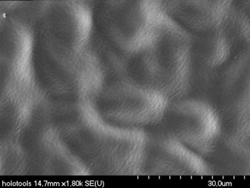

High performance anti-reflection mold

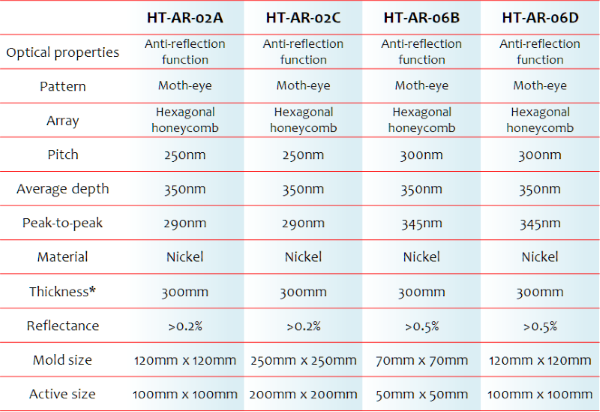

HT-AR-02 and HT-AR-06, which are the culmination of the HT-AR series, are the latest technology nanoimprint molds with a structure developed based on the achievements and know-how in optical design accumulated over many years and our own process development. HT-AR-02 and HT-AR-06 are the latest nanoimprint molds. The moth-eye structure formed on the polymer can reduce the reflectivity to less than 0.2%.

HT-AR series are specially designed for R&D and process development applications, and are available as nickel mold. Standard sizes are available up to 200mm square.

We can also customize the mold size, pitch and depth of the moth-eye structure

as desired by the customer.

Product Specifications

Applications

- Anti-reflection effect

- Water repellent effect (Lotus leaf effect)

- Improved light collection efficiency (solar cells)

Nanoimprinting process example

(Left) Moth-eye structure processed film (Right) Hard coat film

By adding a moth-eye structure to the film surface, it is possible to reduce the reflectivity. The reduction in reflectivity has helped to reduce glare.

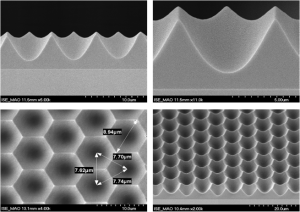

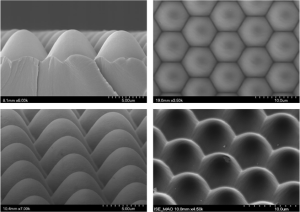

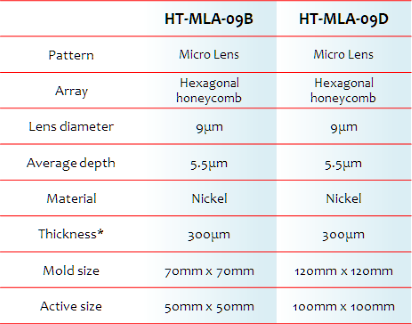

Micro Lens Array (MLA)

The HT-MLA is a microstructure in which the lenses are arranged in a honeycomb configuration in a three-dimensional intersection, and compared to conventional microlenses of the same size, there is no dead space between the lenses. The HT-MLA-09 is specially designed for R&D, process development and process development applications and is available as a standard nickel mold.

Both convex and concave shapes can be produced.

We can also customize the mold size, lens diameter, depth, or elliptical

structure to meet the customer's needs.

Customized Mold Production

Customized Mold Production

Product Specifications

Application

- Improved light extraction efficiency (OLED, LED)

- Improved light collection efficiency (solar cells)

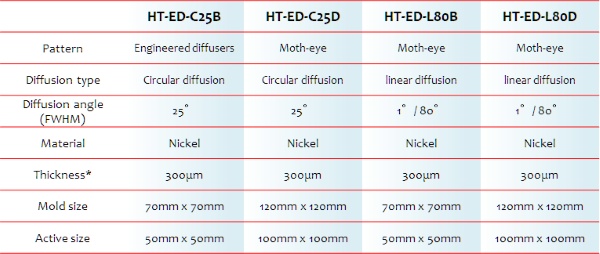

Engineered Diffusers(ED) for the purpose of light control

Engineered Diffuser (ED) is capable of diffusing light evenly while maintaining high transmittance due to its special light distribution structure on the surface. This structure can control the light emitted from general light sources, lasers, LEDs, lighting fixtures, and backlights used in LCDs, etc. The standard HT-ED structures shown here are specially designed for R&D and process development applications, and are available as nickel molds.

It can also be customized for large seamless areas, or for linear or elliptical diffused structures with precisely adjusted diffusion angles.

Customized Mold Production

Customized Mold Production

Product Specifications

Nanoimprinting process example

Without structure |

Circular diffusion |

linear diffusion |

| It is possible to control the direction of light diffusion by designing the structure based on optical design. The circular diffusion structure diffuses the light in all directions with the same diffusion angle, so the light of the laser pointer spreads in a circle. In the linear diffusion structure, the diffusion angle is designed to be different in the vertical and horizontal directions, so that the laser pointer light diffuses in only one direction and forms a line. |

||

Application

- Diffuse light control

- Projector Screen